At the Global Pet Expo in March of 2020, the Pet Sustainability Coalition, Earth Animal, and Pet Food Experts announced a unique Flex Forward Pilot Program. Since August 2020, retailers from across the nation have been working toward a collective mission to gather 5,000 pounds of pet food packaging in an effort to identify sustainable alternatives to the packaging disposed of in landfills.

In December 2020, the first 3,200 pounds of the collected packaging left the PFX Pacific Northwest distribution center in Fife, Washington and arrived at Engineered Plastics, Inc. (EPI) in Erie, PA, to begin the sorting and testing process. Michael Cody, Head of Digital Marketing and Sustainability from Earth Animal and I took the journey out to Pennsylvania to meet with Kurt Duska from EPI to experience the initial recycling testing firsthand.

Sorting Through Collected Packaging

When the two bulk boxes initially arrived at EPI's facilities, Kurt did the initial sorting. Successfully, he was able to sort through one of the bulk boxes of packaging, about 1,600 pounds of materials himself. This effort took approximately 26 hours using his in-depth knowledge of materials from over 30 years in the plastics packaging industry.

Overall, the variety of bags collected was staggering. Among the materials, were several hundred types of bags, as well as, brands. However, the entire recycling team, including Kurt, was amazed at how clean all of the bags were, as most of them seemed brand new or washed. Kudos to our participating retailers and their customers for making our job a little easier and a whole lot cleaner!

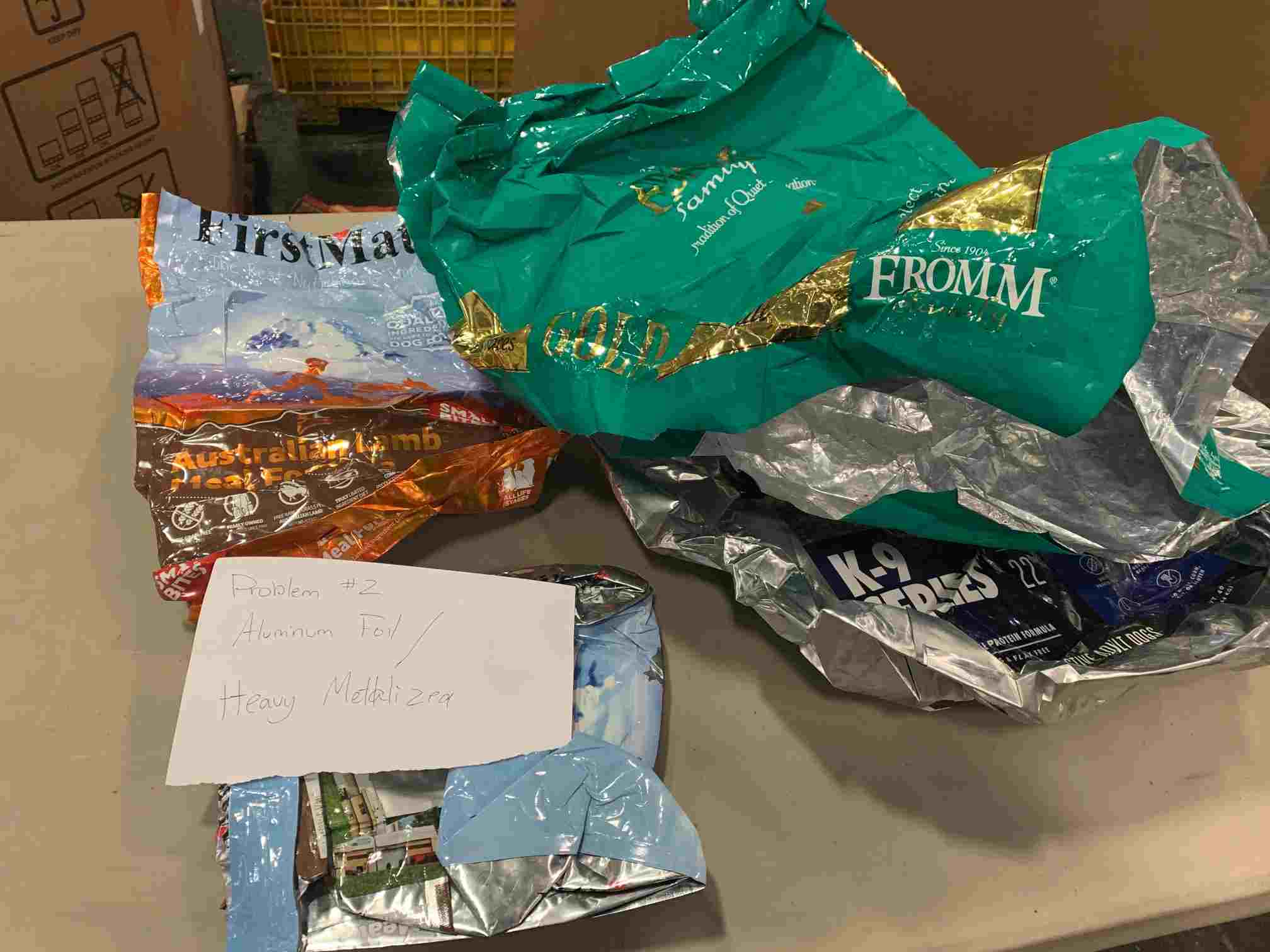

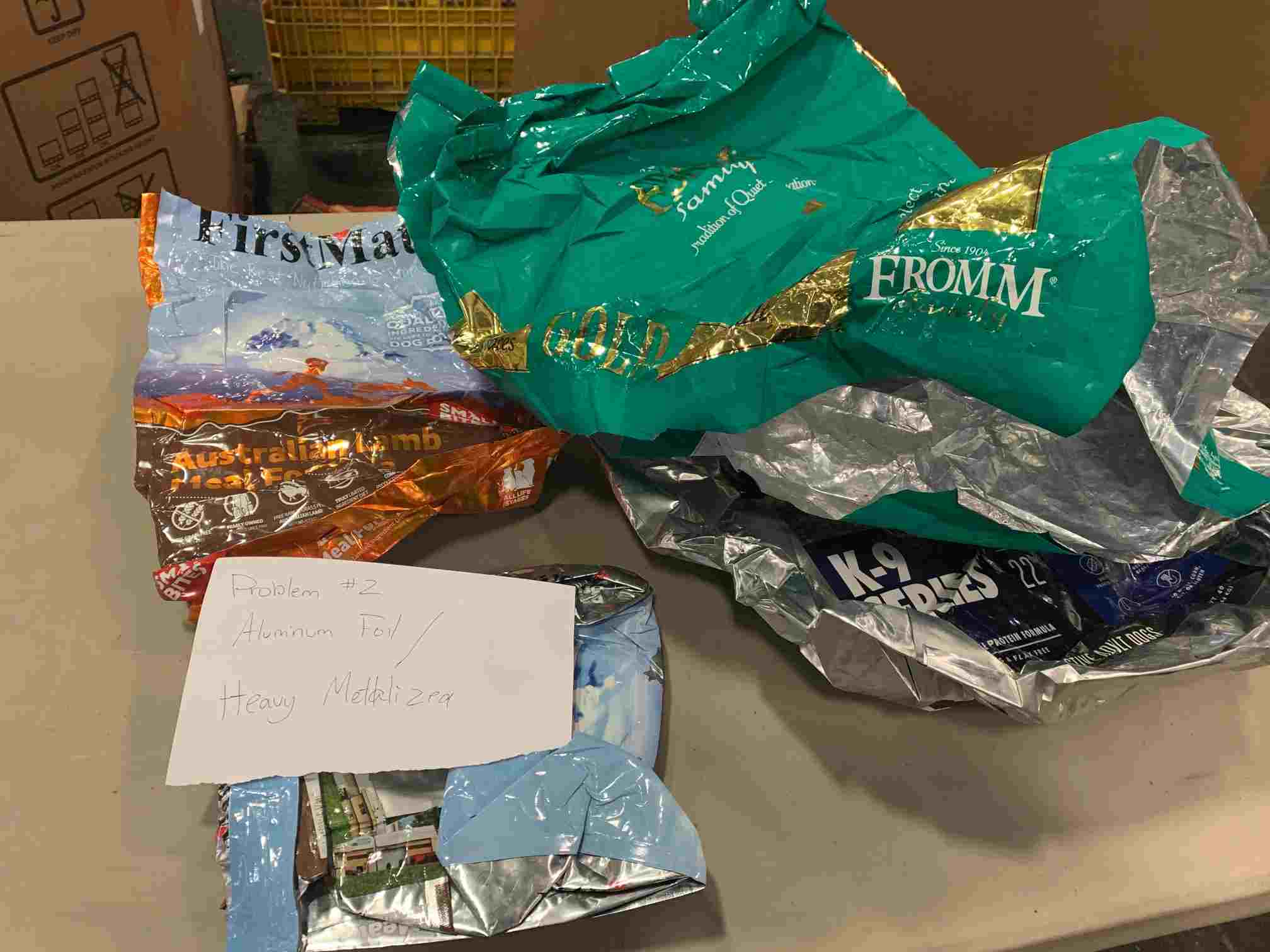

A small portion of the bags collected through the Flex Forward Pilot Program.

A small portion of the bags collected through the Flex Forward Pilot Program.

The collected materials were then separated into three categories, A, B, and C. With each category adding up to just over 500 pounds. The "A" classified materials had the best chance of progressing through the recycling process and were separated using criteria, including the plastic's feel and performing a melting test on the bags to try and determine the type of plastics used within.

Above, you can see the very sophisticated melting test used to determine the types of plastic used within some of the collected packaging.

Above, you can see the very sophisticated melting test used to determine the types of plastic used within some of the collected packaging.

The "B" classified materials were bags deemed problematic for recycling, but not trash. The packaging in this category had materials that made recycling difficult, such as metal or paper layers or a high PE and PET mix. For example, two different types of plastic typically combined to make multi-layer bag.

These bags were sorted into stream B due to the shiny layers inside and outside the packages.

These bags were sorted into stream B due to the shiny layers inside and outside the packages.

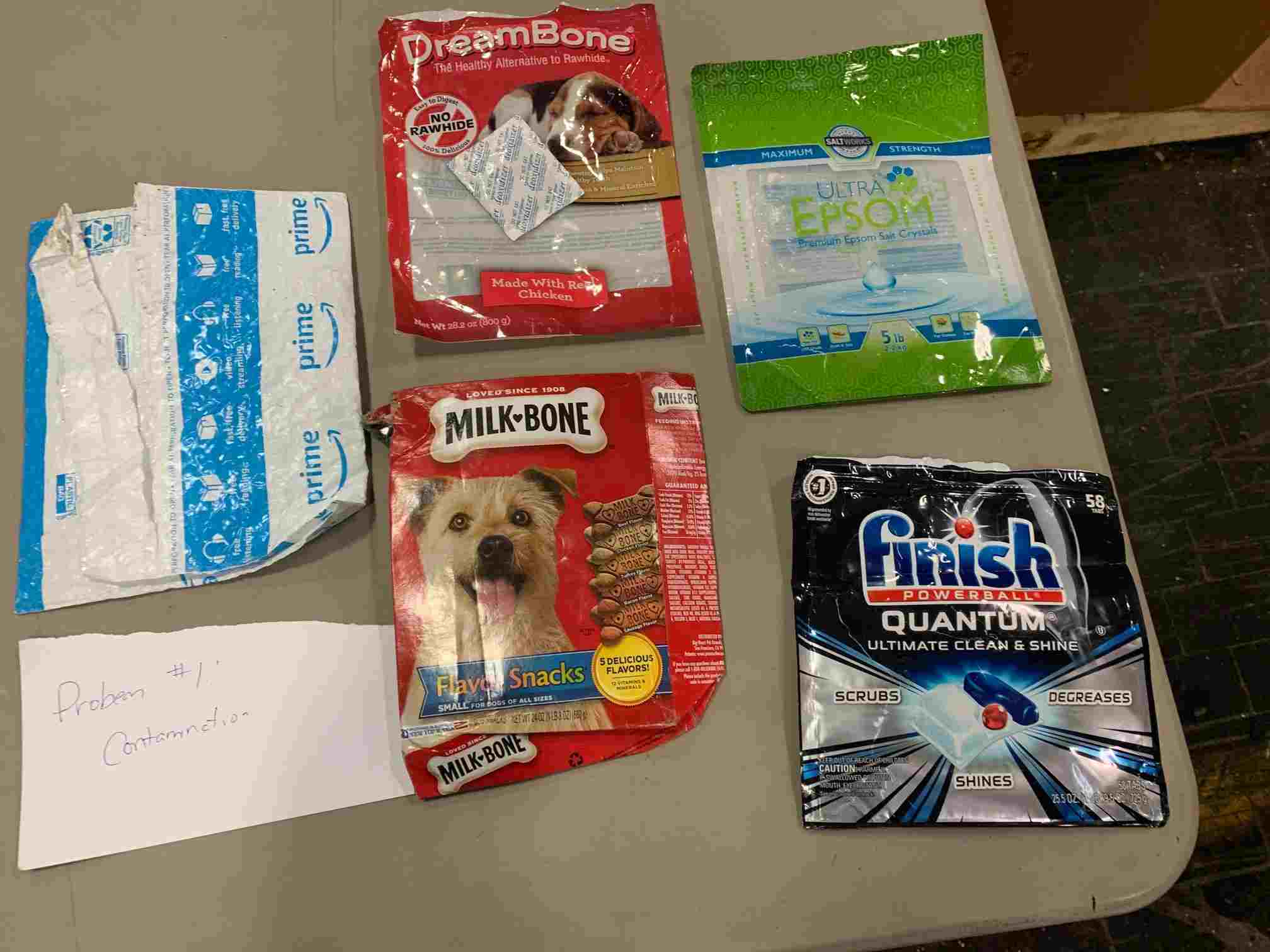

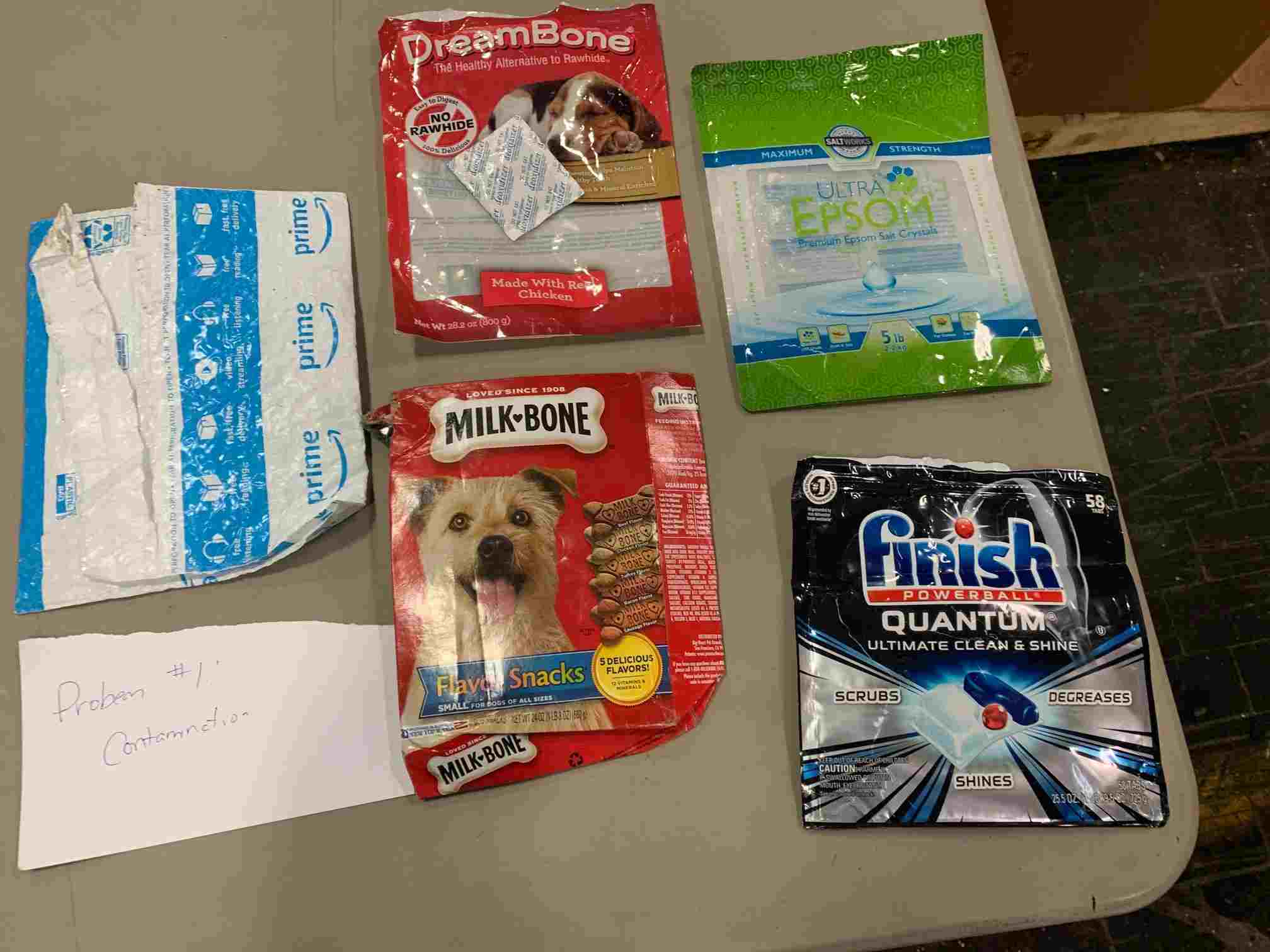

The "C" classified materials were unfortunately not able to be tested for recyclability; these materials included items such as cardboard boxes, Amazon letters, dishwasher detergent bags, etc. The vast majority of these materials, though, were pet packaging. The design was composed of all or primarily non-recyclable materials, such as foil cat treat bags, pet food bags made mainly of metal or foil, or agriculture feed bags. Unfortunately, all of the "C" classified materials were sent to the local landfill.

Many of the collected materials were unfortunately sent to the landfill due to being made from mostly or entirely from non-recyclable material.

Many of the collected materials were unfortunately sent to the landfill due to being made from mostly or entirely from non-recyclable material.

Recycle Testing on the Sorted Packaging

After sorting all the materials, the team attempted to recycle the A materials. The thought was if testing was deemed successful on stream A, then we would move forward with testing stream B. The A materials were loaded onto a conveyor belt, where they passed through a metal detector. The conveyor belt would then drop the materials into a chute where they would be shredded and heated to a specific melting temperature.

This video demonstrates how these materials go from pet food packaging into recycled plastic pellets.

After the materials are shredded and melted, they passed through the first set of filters. Materials caught in the first set of filters included plastic materials with a different melting temperature (such as nylon zippers on bags), inks, food residue, and more. After the first filter, the materials then pass through a second, even finer set of filters where impurities are further filtered out.

The remaining materials were then cooled, shaped into pellets, and collected into large bins. Flex Forward's goal was to successfully turn the collected bags into pellets that would then be turned into products to donate back to pet shelters.

These pellets, ideally, will become products that will be donated to pet shelters.

These pellets, ideally, will become products that will be donated to pet shelters.

The Trials and Tribulations of Recycling

I'm sure you're wondering, did it work? Can we recycle these bags? Well, the answer is... kind of. We had a large amount of difficulty processing the "A" materials. Some of the challenges we encountered included:

- All stream A materials continuously set off the metal detector alarm. Typically, the machine will not function when the metal detector is activated. As a result, a team member had to be placed on the machinery to manually override the alarm during the entire testing period.

- While running the A stream, the equipment had to be shut down for cleaning roughly every 3 minutes, which typically only needs to be done once an hour. Each time it was shut down it took 10-15 minutes to clean meaning the process itself took a long time.

The delays and time constraints caused by these challenges would have large financial implications that need to be addressed if the pilot goes to scale. Despite all that, out of the approximately 500+ pounds of materials in stream A, we were able to get about 300 pounds of pellets which isn't bad. However, due to the difficulties and risk to the equipment, EPI felt it was unsafe to test the B stream, and those materials were landfilled along with stream C.

Moving Forward

We successfully turned 1,600 pounds of materials into 300 pounds of pellets. There is still more to learn as data continues to be collected. Next, NOVA Chemicals will test the 300 pounds of pellets for safety and composition to determine if we can reuse them. As for the other 1,600 pounds of material, we will be putting it through a chemical recycling process to see if that option proves to be more viable.

Understanding that most of the collected bags won't work for mechanical recycling, we are working hard to move the pet industry towards more recyclable bags by promoting our findings and sitting down with suppliers to answer critical questions about how they package their products.

Do metal layers in pet packaging improve shelf life for food, or is that just consumer perception? If only consumer perception, can we change how these bags are designed?

With collections completed, conversations are underway with participating retailers to identify the next steps, celebrate collections success, gather feedback, and encourage retailers to use their voice to push brands towards more recyclable packaging.

It's clear there is still a lot to learn, but overall we are incredibly pleased with how successful the Flex Forward Pilot has been. Big thank you to our partners Earth Animal and Pet Food Experts along with the participating retailers in the Pacific Northwest region for bringing this vision to reality. Stay tuned for continuing updates